Lihlahisoa

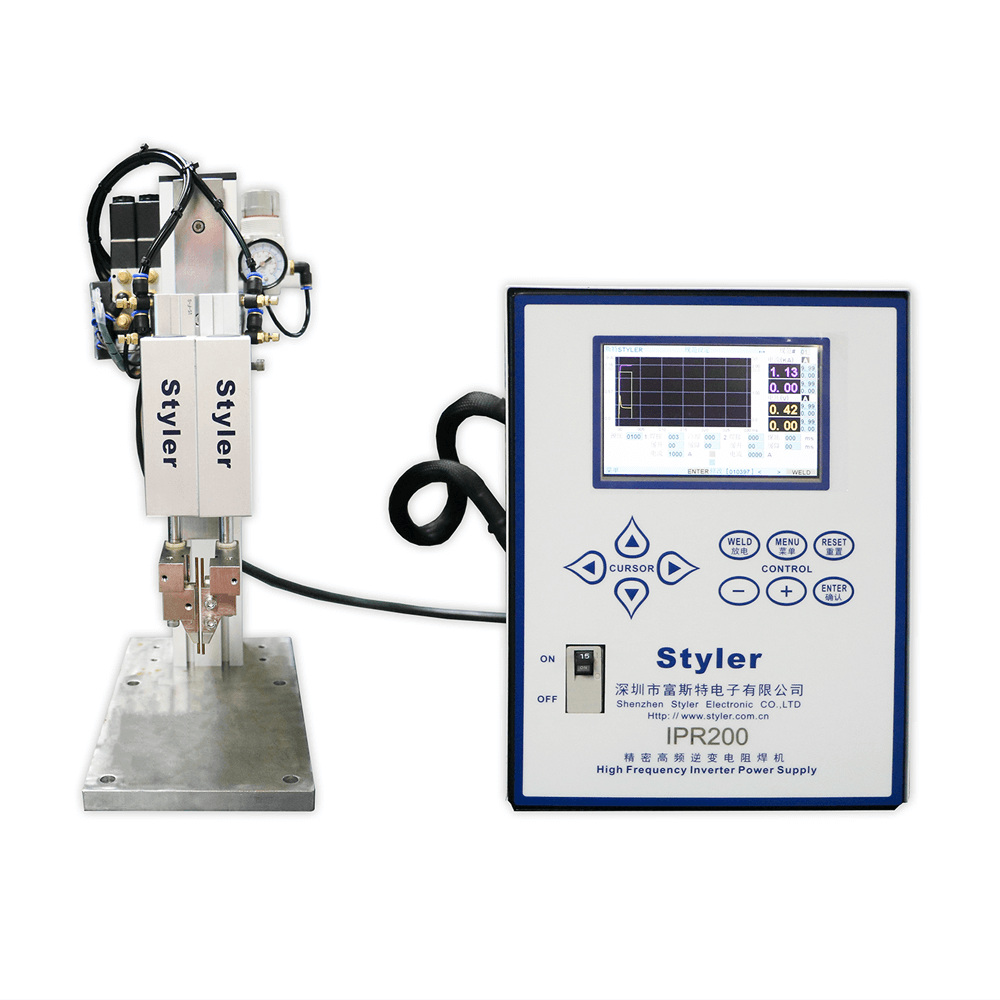

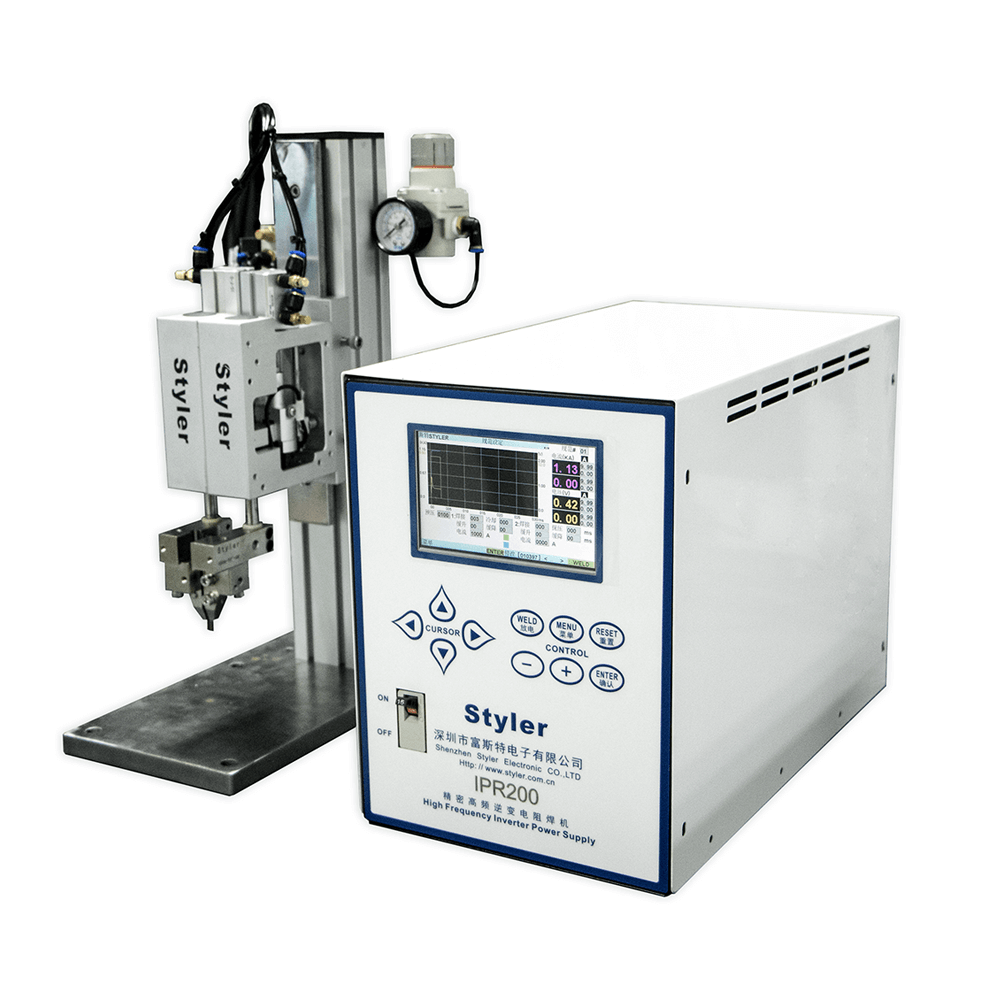

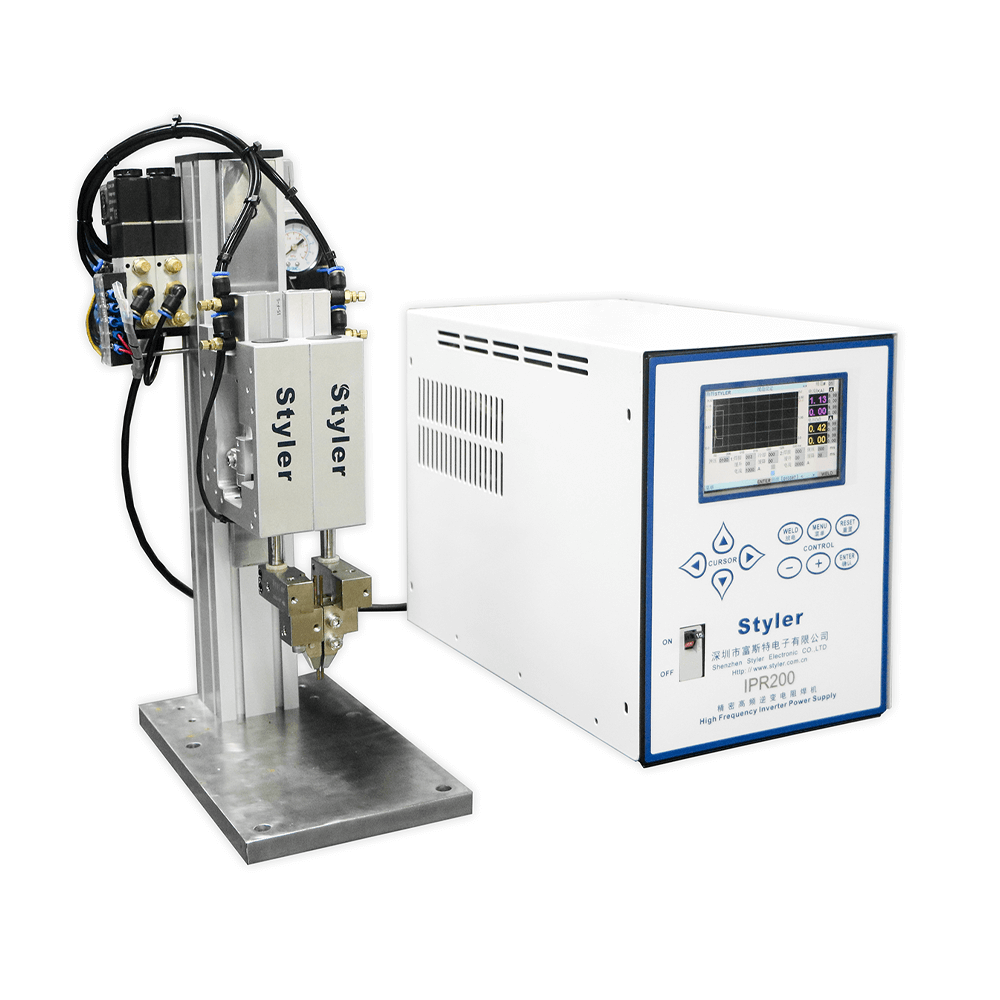

IPV200 Resistance Welding Machine

Likarolo tsa Sehlahisoa

Taolo ea mantlha ea nako le nako, taolo ea motlakase e sa feleng, taolo e tsoakiloeng, ho netefatsa mefuta e fapaneng ea tjheseletsa. Sekhahla sa taolo e phahameng: 4KHz.

Ho fihla ho 50 e bolokiloeng mohopolong oa li-welding, o sebetsanang le mosebetsi o fapaneng.

Sefafatsi se fokolang sa welding bakeng sa sephetho se hloekileng le se setle sa welding.

Ho tšepahala ho phahameng le bokhoni bo phahameng.

Lintlha tsa Sehlahisoa

Tšobotsi ea Parameter

| MO DEL | IPV100 | IPV200 | IPV300 | IPV500 |

| LIEKETSENG ELEC TRICAL | boholo ba nako: 1500A | boholo ba nako: 2500A | boholo curr:3500A | boholo ba nako:5000A |

| LIEKETSENG ELEC TRICAL | ha ho boima ba motlakase: 7 .2V | ha ho boima ba motlakase: 8.5V | volt e se nang moroalo 9 | ha ho boima ba motlakase: 10V |

| ho kenya letsoho: 3 mohato 340 ~ 420VAC 50 / 60Hz | ||||

| E REDITSOE MOKHOA OA PHETOHO | 3.5KVA | 5.5KVA | 8.5KVA | 15KVA |

| MOLAOLI | haholo-holo const curr, const . Volt , motsoako oa motlakase oa motlakase: 00.0% ~ 99 .9% | |||

| TAOLI PHOMOLO | curr: 200 ~ 1500A | curr: 400 ~ 2500A | curr: 400 ~ 3500A | lebelo: 800 ~ 5000A |

| ho nyoloha butle 1, ho nyoloha butle 2:00 ~ 49ms | ||||

| nako ea ho cheselletsa 1:00 ~ 99ms; nako ea ho cheselletsa 2:000 ~ 299ms | ||||

| fokotsa nako 1; fokotsa nako 2:00 ~ 49ms | ||||

| tlhōrō ea boleng ba curr: 0-8000 | ||||

| PHEKO NAKO | nako ea khatello ea maikutlo: 0000 ~ 9999ms | |||

| Nako ea ho futhumatsa poleiti ea welding: 000 ~ 999ms | ||||

| ho tšoara nako ka mor'a ho tjheseletsa: 000 ~ 999ms | ||||

| TS'ELISO TS'OANE | moea | |||

| EX.SIZE | 215(W)X431( D)X274(H)mm | |||

| PHAKISA KHOLO | 280(W)X530( D)X340(H)mm | |||

| GW | 17KG | 23KG | ||

Lisebelisoa tsa boikhethelo

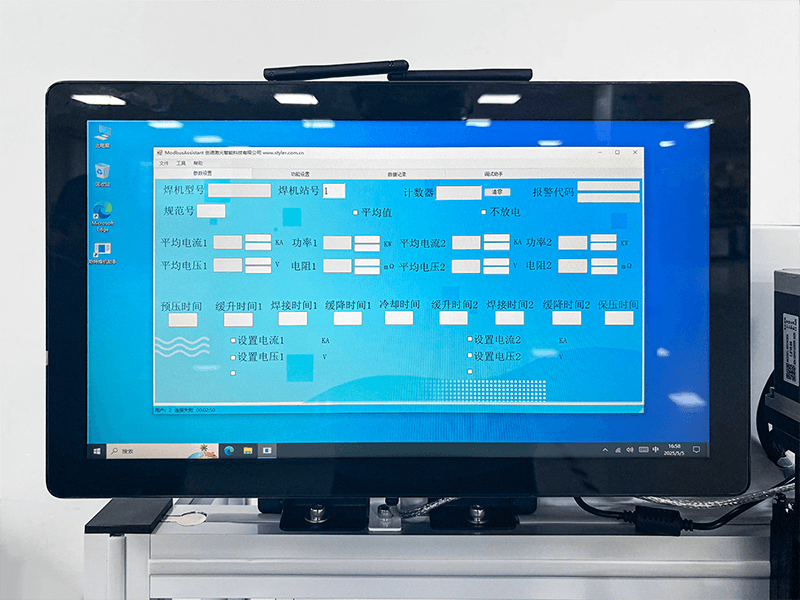

Khomphuta (ho hlahloba ka nako ea sebele ea li-solder, lintlha li ka romelloa ka RS485)

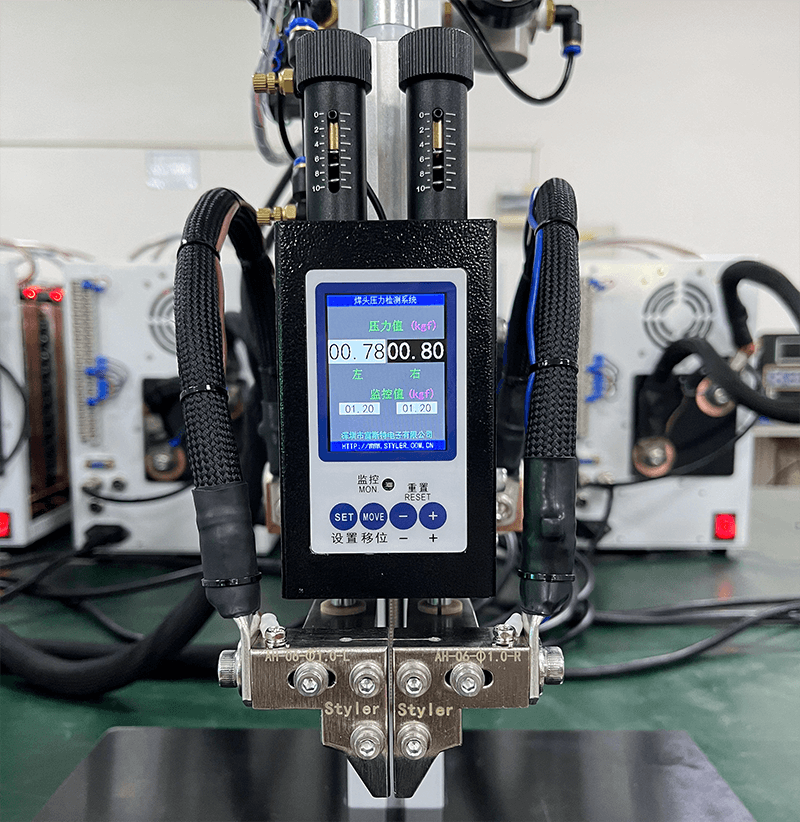

Eketsa sensor ea khatello hloohong ea welding (khatello ea li-clamps mahlakoreng ka bobeli e ka beoa hore e tsitsane, 'me khatello nakong ea welding e ka beoa leihlo)

Ke Hobane'ng ha U Re Khetha

-Na re tšehetsa OEM kapa ODM?

-Na pente ea mantlha ea tlhahiso ea R&D e tla ba le molemo oa theko?

-Na u lihlahisoa tsa boleng bo holimo?

-Na re na le sehlopha se setle?

-Na sehlahisoa sa rona se tšehetsa tšebeletso ea lefatše ka mor'a thekiso?

-Na sehlahisoa sa rona se netefalitsoe?

karabo e 'ngoe le e' ngoe ke "YES"

Tsebo e Tumileng ea Saense

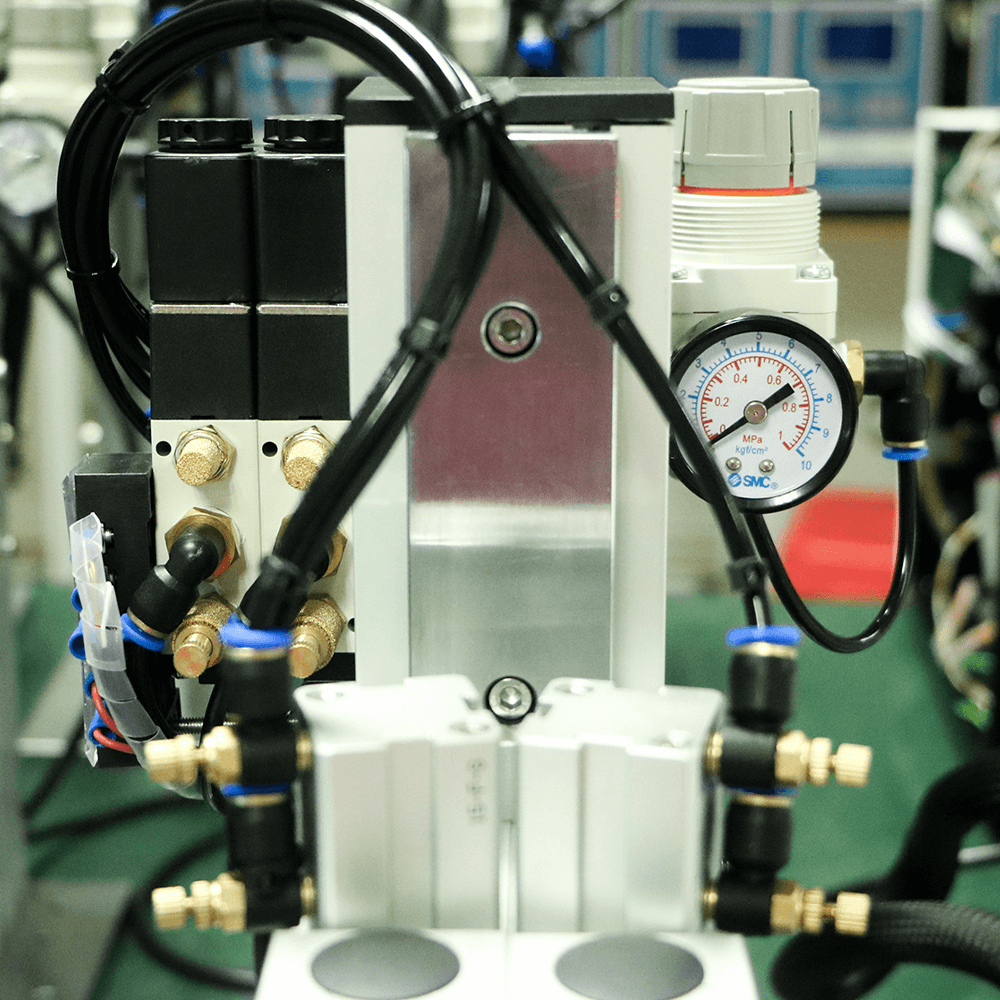

Mochini ona oa pneumatic spot welding o sebelisoa haholo bakeng sa 18650 cylinder call pack welding, o ka cheselletsa botenya ba "nickel" ho tloha ho 0.02-0.2 mm ka phello e ntle ea welding.

Moetso oa Pneumatic o na le molumo o monyane le boima ba 'mele, o bonolo bakeng sa thomello ea machabeng.

Nale ea ntlha ea Sinlge e ka sebelisoa bakeng sa Ni tab weld e nang le kesi ea Stainless steel.

1. Taolo ea microcomputer, CNC e lokisa hona joale.

2. Matla a holimo a nepahetseng a ho tjheseletsa.

3. Pontšo ea li-tube tsa dijithale, taolo ea keyboard, li-parameter tsa welding flash storage.

4. Ho tjheseletsa ha pulse habeli, etsa hore welding e tiee haholoanyane.

5. Litlhase tse nyane tsa welding, ponahalo ea seaparo sa solder e kopaneng, bokaholimo bo hloekile.

6. Linako tsa welding li ka behoa.

7. E ka beha nako ea ho kenya pele, nako ea ho ts'oara, nako ea ho phomola, lebelo la welding le ka fetoloa.

8. Matla a maholo, a tsitsitseng le a ka tšeptjoang.

9. Khatello ea nale e habeli e fetolehang ka thoko, E loketse botenya bo fapaneng ba mochini oa Nickel.