Lefatšeng le ntseng le fetoha ka potlako la tlhahiso ea betri-ho matlafatsa ntho e ngoe le e ngoe ho tloha ho li-EV ho isa ho lisebelisoa tsa elektroniki tsa bareki le polokelo ea grid-welding e eme e le ts'ebetso ea bohlokoa, empa hangata e le phephetso, bakeng sa kopano ea pakete ea betri. Botšepehi ba khokahano e 'ngoe le e' ngoe bo ama polokeho ea pakete, ts'ebetso le nako e telele ea bophelo. Ho STYLER, re sebetsa ka thata ho litharollo tse tsoetseng pele tsa welding le kopano bakeng sa kopanyo ea boemo ba pakete, ho kenyelletsa le Precision Resistance.Spot Welders, Mechini ea Welding ea Laser ea lebelo le holimo, le Turnkey Battery Module & Pack Assembly Lines.

We'Re bokelletse lipotso tse leshome tse atisang ho botsoa ke sehlopha sa rona sa boenjiniere mabapi le ho tjheseletsa lipakete tsa betri, re fana ka temohisiso ea litsebi ho u thusa ho sebetsana le mathata a eona.

1. Ke mokhoa ofe o loketseng oa ho tjheseletsa oa ho hokahanya li-module tsa cylindrical cell kapa li-battery pack busbars?

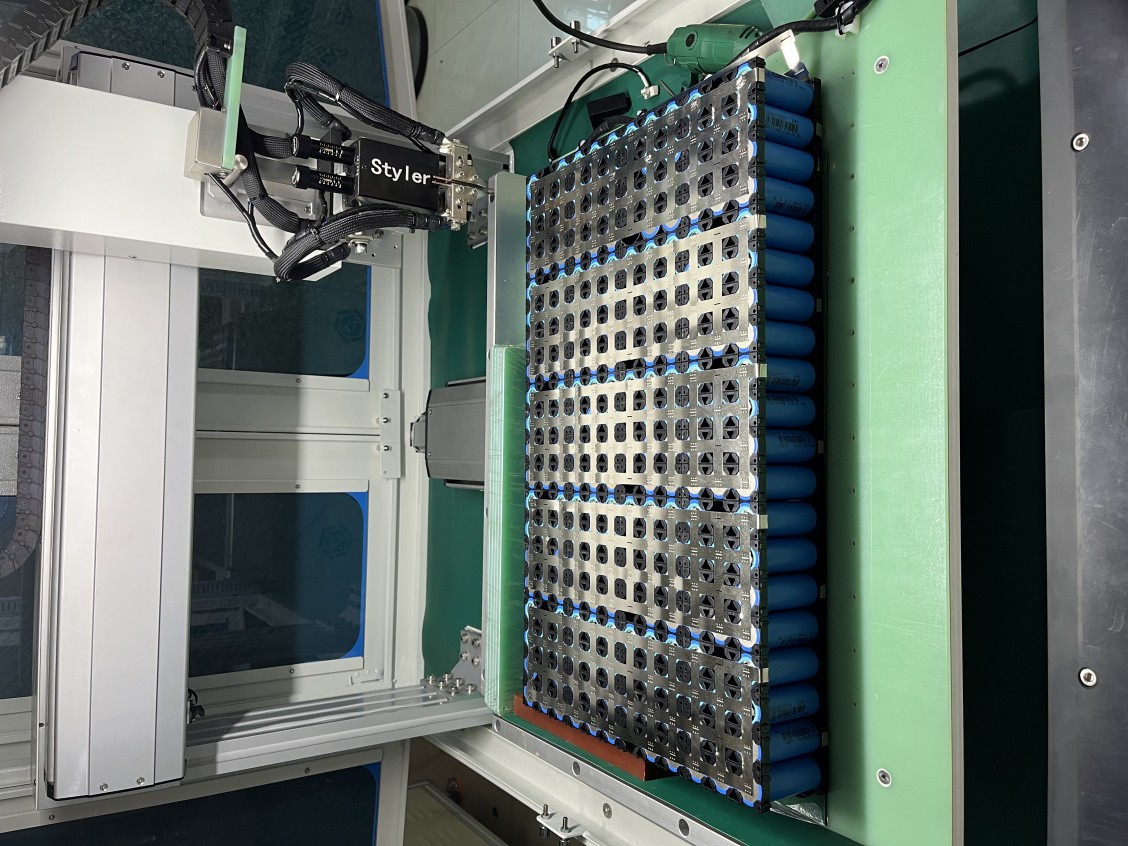

Bakeng sa ho hokahanya lisele ho li-module kapa ho kopanya libese ka har'a pakete, Resistance Spot Welding hangata ke khetho e ratoang. Eona'mokhoa o potlakileng, o sa sebetseng hantle, le o tšepahalang oa ho theha likhokahanyo tse ngata tse matla tsa motlakase. Setšoantšo sa STYLER letheba welders, ho sebelisa theknoloji e tsoetseng pele ea transistor, ho fana ka lebelo le tsitsitseng le botsitso, ka maikutlo a kamehla a hona joale le taolo e feto-fetohang ho sebetsana le lisebelisoa tse tšesaane, tse nang le bokooa tse kang busbar e entsoeng ka nickel.

2. Re ka thibela ho chesa le ho senyeha ha mocheso joang liseleng tsa betri nakong ea ho cheselletsa pakete?

Tsamaiso ea mocheso nakong ea kopano ea pakete ke ea bohlokoa. Ntho ea bohlokoa ke ho laola ho kenya matla ka ho nepahala ho feteletseng libakeng tsa ho hokahanya. Li-welding tsa rona tsa Transistor-based Resistance Spot Welders li fihlela sena ka li-welding tse khutšoane, tse behiloeng hantle ka nako (milliseconds), ho fokotsa ho ata ha mocheso. Bakeng sa welding ea laser, ho khetha li-parameter tse nepahetseng le ho sebelisa li-scanner tsa galvanometer tsa lebelo le holimo ho kenya letsoho mocheso. Sistimi ea rona e ka kopanya tlhahlobo ea mocheso ho netefatsa hore lisele tse haufi li lula li le ka har'a meeli e sireletsehileng.

3. Lisebelisoa tsa aluminium le koporo-aluminium li tloaelehile ka har'a li-pack busbar. Litharollo tsa welding ke life?

Ho cheselletsa lisebelisoa tsena ho hloka khetho e hlokolosi ea ts'ebetso. Bakeng sa ho cheselletsa letheba, boleng bo holimo ba nickel bo hloka hore ho be le boemo bo holimo ka nako e khuts'oane haholo. Li-welder tsa transistor tsa STYLER li fana ka matla a hlokahalang a potlakileng, a tsitsitseng. Bakeng sa welding ea laser ea aluminium busbar le likhokahano, e sebetsa haholo. Leha ho le joalo, bakeng sa libese tsa koporo feela tse kopaneng tsa pakete, welding ea laser e hlahisa liphephetso ka lebaka la ponahalo e phahameng le conductivity ea mocheso. Ntho e 'ngoe e sebetsang le e khothalletsoang ke ho sebelisa li-busbars tse entsoeng ka koporo-aluminium (lisebelisoa tse apereng), moo laser weld e etsoang holim'a lera la aluminium, ho netefatsa hore ho na le motsoako o ka tšeptjoang le o tsitsitseng haholoanyane.

4. Bohloeki ba lintho tse bonahalang le ho lokisa bokaholimo bakeng sa ho cheselletsa pakete ke tsa bohlokoa hakae?

E nyatsa haholo. Li-oxides, oli, le litšila libareng tsa libese kapa li-terminals li baka boleng bo sa tsitsang ba weld, ho eketseha ha matla a motlakase, le ho hloleha ho ka bang teng. Ts'ebetso e matla ea ho kopanya pakete e tlameha ho kenyelletsa tlhoekiso e nepahetseng (mohlala, ho hloekisa ka laser, ho hloekisa plasma) hang-hang pele ho tjheseletsa. Mehala ea Kopano ea Battery Pack ea STYLER e ka kopanya liteishene tsa ho hloekisa ka boiketsetso ho netefatsa maemo a ts'oanang a holim'a likhokahano tsohle.

5. Re etsa bonnete ba hore boleng bo tsitsitseng ba weld tlhahisong ea lipakete tse phahameng?

Consistency e tsoa ho botsitso ba lisebelisoa, tlhahlobo ea ts'ebetso le boiketsetso. Mechini ea rona e na le:

Tlhokomelo ea Ts'ebetso ea Nako ea 'Nete: Ho lekanya khanyetso e matla (spot welding) bakeng sa weld e ngoe le e ngoe.

Koala-Loop Adaptive Control: Ho ikamahanya le maemo ho ipapisitse le maikutlo.

100% Tlhahlobo ea Post-Weld: Ho kopanya litsamaiso tsa pono bakeng sa ho beoa ha weld le liteko tsa ho hanyetsa motlakase moleng oa kopano bakeng sa netefatso ea boleng.

6. Melemo ea bohlokoa ea ho tjheseletsa ka laser kopanong ea pakete ea betri ke efe?

Laser Welding e fana ka phetoho e ikhethang ho jiometry ea weld (mela, selikalikoe, li-contours), khatello e nyane ea mochini, le bokhoni ba ho tjheseletsa libakeng tse koaletsoeng ka har'a sebopeho sa pakete. E loketse lipoleiti tsa ho qetela tsa mojule oa welding, li-seams tse koahelang (moo ho hlokahalang), le libopeho tse rarahaneng tsa busbar. E fokotsa ho roala ha lisebelisoa 'me e nolofalletsa seams tse lebelo le holimo, tse hloekileng ka bokhabane.

7. Battery Pack Assembly Line e hlokahala neng ha e bapisoa le li-welders tse ikemetseng?

Li-welders tse ikemetseng li nepahetse bakeng sa R&D, mehala ea lifofane, kapa mehato e ikhethileng ea kopano. Mohala oa Kopano oa Battery Pack oa Turnkey o bohlokoa bakeng sa tlhahiso e kopaneng, e phahameng haholo ea li-module kapa lipakete tse felletseng. STYLER e rala mela e tsamaisang tatellano eohle ka boiketsetso: ho beoa ha module, ho beoa ka libese, welding (letheba kapa laser), tlhahlobo ea motlakase, le kopanyo ea ho qetela. Sena se eketsa ts'ebetso, se fokotsa liphoso tsa batho, se netefatsa ts'ebetso, 'me se ntlafatsa sebaka sa fatše.

8. U sebetsana joang le weld spatter ka har'a pakete ea betri, e ka bakang li-circuits tse khutšoane?

Ho fafatsa ka har'a pakete ke kotsi e kholo ea polokeho. Ho tjheseletsa ka libaka, ho laoloa ka ho ntlafatsa sebopeho sa pulse ea weld le matla a electrode. Li-Spot Welder tsa rona tse thehiloeng ho Transistor li fana ka taolo e phahameng ea pulse, li fokotsa haholo tlhahiso ea spatter. Ho tjheseletsa ka laser, spatter e fokotsoa ka ho sebelisa khase e nepahetseng ea tšireletso, boemo bo botle ba focus, le liparamente tse etselitsoeng uena. Litsamaiso tsa STYLER li hlophisitsoe ho hlahisa li-weld tse hloekileng, tse fokolitsoeng ke spatter tse bohlokoa bakeng sa polokeho ea pakete.

9. Ke metrics efe eo re lokelang ho e sebelisa ho netefatsa boleng ba weld ka har'a pakete?

Ntle le tlhahlobo ea pono, metrics ea bohlokoa ea netefatso e kenyelletsa:

Motlakase Resistance/Conductivity: E lekanngoa ho pholletsa le lenonyello le leng le le leng la weld; khanyetso e tlase le e tsitsitseng e bohlokoa bakeng sa ts'ebetso ea pakete.

Matla a Hula / Peel: Teko e senyang ea mochini ho lisampole ho netefatsa hore botšepehi ba khokahano bo kopana le litlhaloso.

Ho Kena ha Nugget / Seam: E netefalitsoe ka tlhahlobo ea likarolo tse fapaneng nakong ea ho fumana mangolo.

Ts'ebetso ea Ts'ebetso ea Ts'ebetso: Mekhahlelo e 'ngoe le e' ngoe ea weld (ea hona joale, nako, matla) e tlalehiloe ke lisebelisoa tsa STYLER bakeng sa ts'ebetso e felletseng ea tlhahiso.

10. Indasteri e ikamahanya joang le welding bakeng sa meralo e mecha ea pakete joalo ka CTC (Cell-to-Chassis) kapa liphutheloana tse kholo tsa meralo?

Meralo ena e hloka lits'ebetso tsa welding tse etsang hore ho be le likhokahano tse matla, tse tšepahalang tsa motlakase, 'me ka linako tse ling tsa sebopeho ka bongata bo boholo. Ba sutumelletsa litlhoko tsa botebo ba weld, lebelo, le botsitso. Li-Welders tsa Laser tse Matla a Phahameng li ntse li sebelisoa haholo bakeng sa li-welds tse telele tsa seam ka har'a mekotla ea liphutheloana le libareng tsa meralo. STYLER e ka pele-pele, e nts'etsapele litharollo ka matla a hlokahalang, ho nepahala, le matjato a ho tobana le liphephetso tsena tsa pokello ea liphutheloana tsa moloko o latelang.

Qetello

Battery pack welding ke taeo e nepahetseng e shebaneng le ho theha likhokahano tse phethahetseng tsa motlakase ka har'a kopano e bolokehileng le e tšepahalang. Khetho e nepahetseng ea ts'ebelisano 'moho le thekenoloji ke tsona tse ka sehloohong molemong oa katleho ea sehlahisoa sa hau.

Ho STYLER, re fana ka litharollo tse lebisitsoeng tsa ho kopanya pakete ea betri. Ho tloha ho botsitso ba lebelo le phahameng ba Transistor-based Resistance Spot Welders le ho nepahala ho feto-fetohang ha Laser Welding Systems ho ea ho othomathike e kopaneng ea Battery Pack Assembly Lines ea rona, re ikemiselitse ho matlafatsa tlhahiso ea hau ka ts'epo, boqapi le bokhabane.

Na u se u loketse ho ntlafatsa ts'ebetso ea hau ea ho tjheseletsa lipakete tsa betri? Ikopanye le sehlopha sa litsebi sa STYLER kajeno bakeng sa puisano.

Nako ea poso: Dec-11-2025