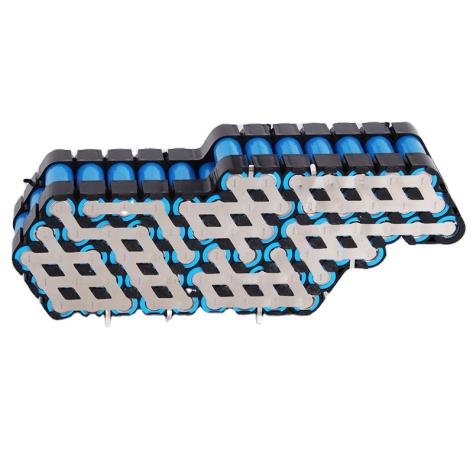

Ha ho etsoa pakete ea betri ea lithium-ion, ts'ebetso ea welding e ama ka kotloloho ts'ebetso, polokeho le botsitso ba pakete e latelang ea betri.Resistance spot weldinglelaser tjheseletsa, e le mekhoa e tloaelehileng, e 'ngoe le e' ngoe e na le litšobotsi tse fapaneng, tse etsang hore li tšoanelehe bakeng sa lisebelisoa tse fapaneng tsa betri le mekhahlelo ea meralo.

Resistance spot welding: Mokhoa o ratoang oa ho cheselletsa maqephe a nickel

Resistance spot welding e sebelisa mocheso oa ho hanyetsa o hlahisoang ke ho feta hona joale ka maqephe a nickel ho theha bond e matla ea metallurgical. Mocheso ona o matla le ts'ebetso ea ho cheselletsa ka potlako e etsa hore e be e loketseng bakeng sa lisebelisoa tsa ho tjheseletsa joalo ka nickel e hloekileng kapa ribone ea nickel, e sebelisoang hangata libetering tsa lithium-ion. Melemo ea eona e holim'a ts'ebetso ea eona ea theko e tlase le ts'ebetso e butsoitseng, e etsang hore e be khetho e tšepahalang bakeng sa welding e phahameng ea li-tab tsa lisele tsa betri le lihokelo.

(Mokoloto: Styler Images)

(Mokoloto: Styler Images)

Laser welding: Mokhoa o nepahetseng oa ho cheselletsa aluminium le lisebelisoa tse tenya

Ha ho tjhesetsoa likhase tsa aluminium, lihokelo tsa aluminium, kapa likaroloana tse teteaneng tsa meralo, welding ea laser e bonts'a melemo ea eona e ikhethang. Matla a matla a laser a phahameng haholo a e lumella ho sebetsana le bese e teteaneng ea aluminium, ho fihlela litšepe tse kenang ka botebo le ho hlahisa litšepe tse khahlehang, tse sa keneng moea. E loketse ho kopanya ka nepo likarolo tsa aluminium ka har'a li-module le lipakete tsa betri.

(Mokoloto: Styler Images)

Moralo oa mohala oa tlhahiso o felletseng ho tloha seleng ho ea ho pakete

Mohala o felletseng oa tlhahiso ea betri ea lithium hangata o kopanya mekhoa e mengata. Ho itšetlehile ka thepa ea hau e khethehileng (nickel / aluminium / koporo) le sebopeho sa betri pakete, re ka kopanya mehato e kang ho hlophisa lisele le busbar welding, ho tloha liseleng ka bomong ho ea ho tlatsa lipakete tsa betri, ho etsa litharollo tsa tlhahiso tse hlophisitsoeng le tse feto-fetohang tse leka-lekaneng katleho, litšenyehelo le ts'ebetso.

Ha ho etsoa li-betri, ha ho na tharollo ea ho tjheseletsa e lekanang boholo bo le bong. Mefuta e fapaneng ea betri hangata e hloka lits'ebetso tse ikhethileng tsa welding. Re utloisisa sena mme re ikemiselitse ho fana ka lisebelisoa tse ngata tse tsoetseng pele tsa ho tjheseletsa ho u thusa ho fumana khetho e ntle ka ho fetisisa. Ho Styler, ha re fane ka lisebelisoa feela; re fana ka mokhoa oa ts'ebetso o lumellanang le litlhoko tsa hau. Bua le rona 'me re sebelise theknoloji e nepahetseng ka ho fetisisa ea ho tjheseletsa ho sireletsa betri ea hau.

Want to upgrade your technology? Let’s talk. Visiting our website http://www.styler.com.cn , just email us sales2@styler.com.cn and contact via +86 15975229945.

Nako ea poso: Oct-15-2025