Lefapheng la tlhahiso, haholo-holo tlhahisong ea libeteri bakeng sa lits'ebetso tse fapaneng, welding e bapala karolo ea bohlokoa ho theheng likhokahano tse matla le tse tšepahalang lipakeng tsabetridikarolo. Bohareng ba katleho ea ho cheselletsa sebaka sa betri ke taolo e nepahetseng ea hajoale, e leng ntho e susumetsang haholo boleng le bots'epehi ba li-welds. Sengoliloeng sena, re hlahloba bohlokoa ba ho tjheseletsa sebaka sa betri hona joale le litlamorao tsa eona ho netefatsa ts'ebetso e nepahetseng le polokeho ts'ebetsong ea tlhahiso.

Ke Hobane'ng ha Mathata a Hona Joale:

Hona joale ke phallo ea tefiso ea motlakase, 'me sebakeng sa ho cheselletsa, e ikarabella bakeng sa ho hlahisa mocheso o hlokahalang ho theha li-welds lipakeng tsa likarolo tsa betri. Boholo ba hona joale bo ama ka ho toba palo ea mocheso o hlahisoang ho sebopeho sa welding, qetellong e lekanyetsa boleng ba weld. Ho haella ha hona joale ho ka baka li-welds tse fokolang kapa tse sa fellang, tse behang kotsing sebopeho sa sebopeho.kopano ea betri. Ka lehlakoreng le leng, hona joale ho feteletseng ho ka baka mocheso o feteletseng, ho qhibiliha, kapa esita le ho senya likarolo tsa betri, ho beha likotsi tsa ts'ireletso le ho ama botšepehi ba betri ka kakaretso.

Ho Ntlafatsa Hona Joale bakeng sa Welding ea Battery Spot:

Ho finyella se loketseng hona joale bakeng satjheseletsa sebakeng sa betrie hloka ho shebisisa lintlha tse 'maloa ka hloko, ho kenyelletsa mofuta le botenya ba lisebelisoa tse cheselitsoeng, moralo oa li-electrode tsa welding, le litlhoko tse ikhethang tsa ts'ebeliso ea betri. Ho feta moo, lintlha tse kang khatello ea li-electrode le nako ea welding li tlameha ho tsotelloa ho netefatsa hore li-welds tse tsitsitseng le tse tšepahalang.

Ka kakaretso, ho cheselletsa sebaka sa betri hangata ho hloka maqhubu ho tloha ho makholo a 'maloa ho isa ho likete tse' maloa tsa li-ampere, ho latela boholo le sebopeho sa lisele tsa betri.Libetri tsa lithium-ion, mohlala, hangata li hloka maqhubu a pakeng tsa 500 ho isa ho 2000 ampere bakeng sa ho cheselletsa letheba, ha e le kholoanyane.lipakete tsa betrie ka hloka maqhubu a phahameng le ho feta ho netefatsa ho kenella ka nepo le ho tlamahanngoa ha likarolo tsa betri.

Ho netefatsa Polokeho le Boleng:

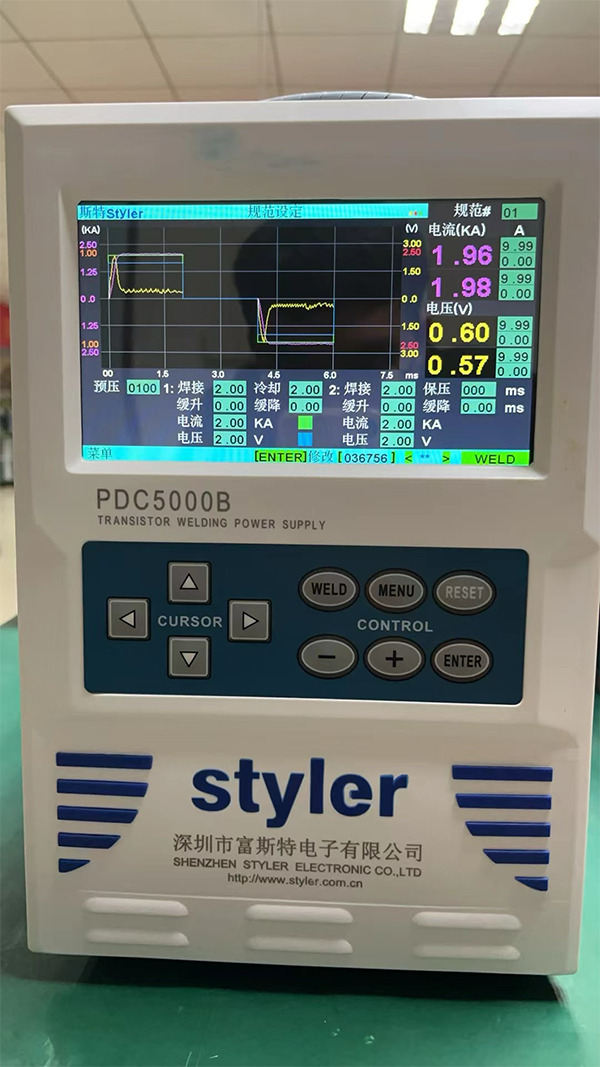

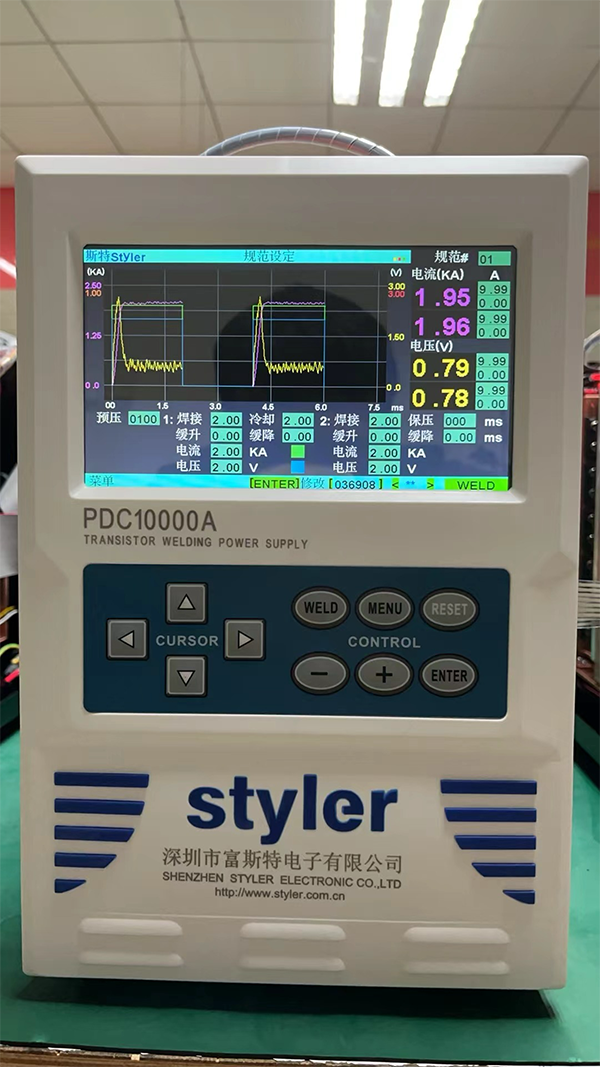

Ha ho nahanoa ka karolo ea bohlokoa ea hona joale ho tjheseletsa libaka tsa betri, ho netefatsa hore taolo e nepahetseng le ho beha leihlo ea hajoale ho bohlokoa ho boloka polokeho le boleng ts'ebetsong ea tlhahiso. Ea kajenometjhini e tjheseletsang lethebae nang le litsamaiso tse tsoetseng pele tsa taolo li fana ka likarolo tse kang tlhahlobo ea nako ea 'nete, li-algorithms tsa ho tjheseletsa tse feto-fetohang, le tokiso ea othomathike ea li-parameter tsa welding, tse nolofalletsang basebelisi ho fihlela boleng bo holimo ba weld ha ba ntse ba fokotsa kotsi ea ho chesa kapa ho senya likarolo tsa betri.

At Setaele, Re sebetsa ka ho khetheha ho rala le ho etsa lisebelisoa tse tsoetseng pele tsa ho tjheseletsa letheba tse etselitsoeng litlhoko tse khethehileng tsa bahlahisi ba betri. Mechini ea rona ea morao-rao e kenyelletsa theknoloji ea morao-rao ea taolo ea morao-rao, e netefatsang li-welds tse nepahetseng le tse tsitsitseng bakeng sa lits'ebetso tse fapaneng tsa betri. Hore na o hlahisa libeteri tsa lithium-ion bakeng sa lisebelisoa tsa elektroniki tsa bareki kapa tse sebetsang hantle hahololikoloi tsa motlakase, litharollo tsa rona tse ncha tsa welding li u fa matla a ho fihlela boleng bo holimo, bots'epehi le polokeho lits'ebetsong tsa hau tsa tlhahiso.

Qetellong, bohlokoa ba hona joale ho tjheseletsa sebakeng sa betri bo ke ke ba feteletsoa. Ka ho utloisisa karolo ea bohlokoa ea mahlale a morao-rao le a sebelisang litheknoloji tsa welding tse tsoetseng pele, baetsi ba betri ba ka ntlafatsa boleng ba weld, ba ntlafatsa ts'epahalo ea sehlahisoa, le ho netefatsa polokeho ea ts'ebetso ea bona. Bakeng sa tlhaiso-leseling e batsi mabapi le mefuta e mengata ea lisebelisoa le lits'ebeletso tsa welding, ka kopo etelahttps://www.stylerwelding.com/kapa ikopanye le sehlopha sa rona se nang le tsebo kajeno.

Lintlha tse fanoeng ke Styler (“rona,” “rona” kapa “rona”) hohttps://www.stylerwelding.com/

("Sebaka") ke molemong oa tlhaiso-leseling feela. Lintlha tsohle tse fumanehang sebakeng sena sa Marang-rang li fanoe ka tumelo e ntle, leha ho le joalo, ha re etse tlhahiso kapa tiisetso ea mofuta ofe kapa ofe, ho hlalosa kapa ho fana ka maikutlo, mabapi le ho nepahala, ho lekana, ho nepahala, ho tšepahala, ho fumaneha kapa ho phetheha ha tlhahisoleseding efe kapa efe ho Site. TLAS'A MAEMO HA HO MAEMO A RE KE RE BA LE BOIKARABELO HO WENA BAKENG SA Tahlehelo KAPA TSEBE EFE EA MOFUTA O MANG KAPA O ETSANG KA LA SEBEDISO EA SEBAKA KAPA HO ITŠEPA LINTLHA TSE LING TSE FUMANEHANG SEBENG. TŠEBELETSO EA HAO EA SEBAKA LE HO ITŠEPA HA HAO TSEBISO EFE KA EFE E ENESITE KE HO FEELA MOKGWA OA HAO.

Nako ea poso: Mar-19-2024