Lihlahisoa

Mochini oa ho Welding oa PDC6000A Spot

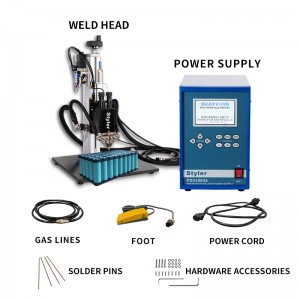

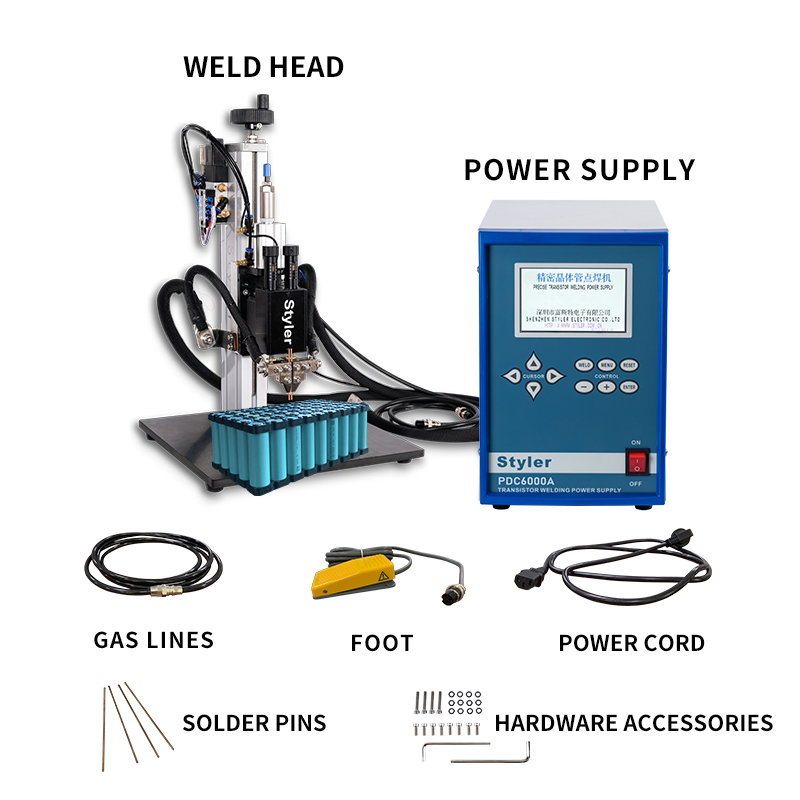

Likarolo tsa Sehlahisoa

Mokhoa oa ho laola motlakase o sa khaotseng, motlakase o sa khaotseng le oa lebasetere o amoheloa ho netefatsa hore ts'ebetso ea welding e fapana.

Sesepa se seholo sa LCD, se ka bonts'ang hona joale oa welding, matla le voltage lipakeng tsa li-electrode, hammoho le khanyetso ea ho ikopanya.

Ts'ebetso ea ho lemoha e hahiloeng ka hare: pele ho matla a molao, motlakase oa ho lemoha o ka sebelisoa ho netefatsa boteng ba mosebetsi oa mosebetsi le boemo ba mosebetsi.

Mohloli oa matla le lihlooho tse peli tsa welding li ka sebetsa ka nako e le 'ngoe.

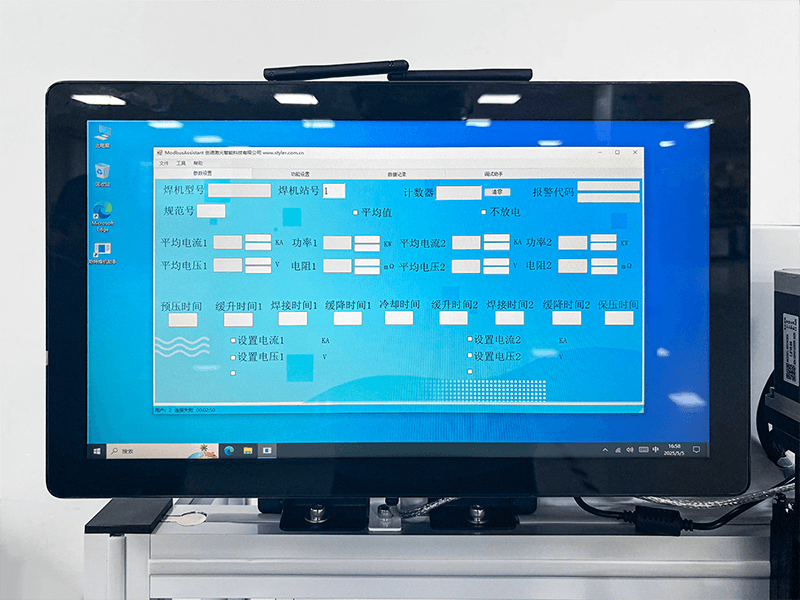

Likarolo tsa 'nete tsa welding li ka hlahisoa ka boema-kepe ba serial ba RS-485.

E ka fetola lihlopha tse 32 tsa matla ntle ho mabaka ka likoung tse kantle.

Lipontšo tse feletseng tsa ho kenya le ho hlahisa, tse ka sebelisoang hammoho le tekanyo e phahameng ea ho iketsetsa. E ka fetola le ho letsetsa li-parameter ka remoutu ka protocol ea Modbus RTU.

Sesebelisoa sa Sehlahisoa

E ka tjheseletsa thepa e sa tšoaneng e khethehileng, haholo-holo e loketseng ho hokahanya ha tšepe e sa hloekang, koporo, aluminium, nickel, titanium, magnesium, molybdenum, tantalum, niobium, silevera, platinum, zirconium, uranium, beryllium, lead le li-alloys tsa tsona. Likopo li kenyelletsa liteishene tsa micromotor le lithapo tsa enamelled, plug-in components, libeteri, optoelectronics, cables, piezoelectric crystals, sensitive components le sensors, capacitor le lisebelisoa tse ling tsa elektroniki, lisebelisoa tsa bongaka, mefuta eohle ea lisebelisoa tsa elektroniki tse nang le li-coil tse nyane tse hlokang ho ts'oaroa ka kotloloho ka lithapo tsa enamelled tse sa fihlelle litlhoko tse ling tsa welding le lisebelisoa tse ling tse phahameng. litlhoko tsa ts'ebetso.

Lintlha tsa Sehlahisoa

Tšobotsi ea Parameter

| Lisebelisoa tsa lisebelisoa | |||||

| MOHLALA | PDC10000A | PDC6000A | PDC4000A | ||

| MAX CURR | 10000A | 6000A | 2000A | ||

| MAX MATLA | 800W | 500W | 300W | ||

| MOFUTA | STD | STD | STD | ||

| MAX VOLT | 30V | ||||

| KEKETSO | mohato o le mong 100 ~ 120VAC kapa phase200 ~ 240VAC 50/60Hz | ||||

| MOLAOLI | 1 .const , curr;2 .const , volt;3 .const . motsoako oa curr le volt;4 .const matla;5 .const .curr le motsoako oa matla | ||||

| NAKO | nako ea khatello ea maikutlo: 0000 ~ 2999ms ho hanyetsa pele ho lemoha tjheseletsa nako: 0 .00 ~ 1 .00ms nako ea ho lemoha pele: 2ms (e tsitsitseng) nako ea ho phahama: 0 .00 ~ 20 .0ms ho hanyetsa pele ho lemoha 1, 2 nako ea ho tjheseletsa: 0 .00 ~ 99 .9ms nako ea ho fokotsa nako: 0 .00 ~ 20 .0ms nako ea ho pholile: 0 .00 ~ 9 .99ms nako ea ho ts'oara: 000 ~ 999ms | ||||

| LIEKETSENG

| 0.00~9.99KA | 0.00~6.00KA | 0.00~4.00KA | ||

| 0.00~9.99v | |||||

| 0.00~99.9KW | |||||

| 0.00~9.99KA | |||||

| 0.00~9.99V | |||||

| 0.00~99.9KW | |||||

| 00.0 ~ 9.99MΩ | |||||

| CURR RG | 205(W)×310(H)×446(D) | 205(W)×310(H)×446(D) | |||

| VOLT RG | 24KG | 18KG | 16KG | ||

Lisebelisoa tsa boikhethelo

Khomphuta (ho hlahloba ka nako ea sebele ea li-solder, lintlha li ka romelloa ka RS485)

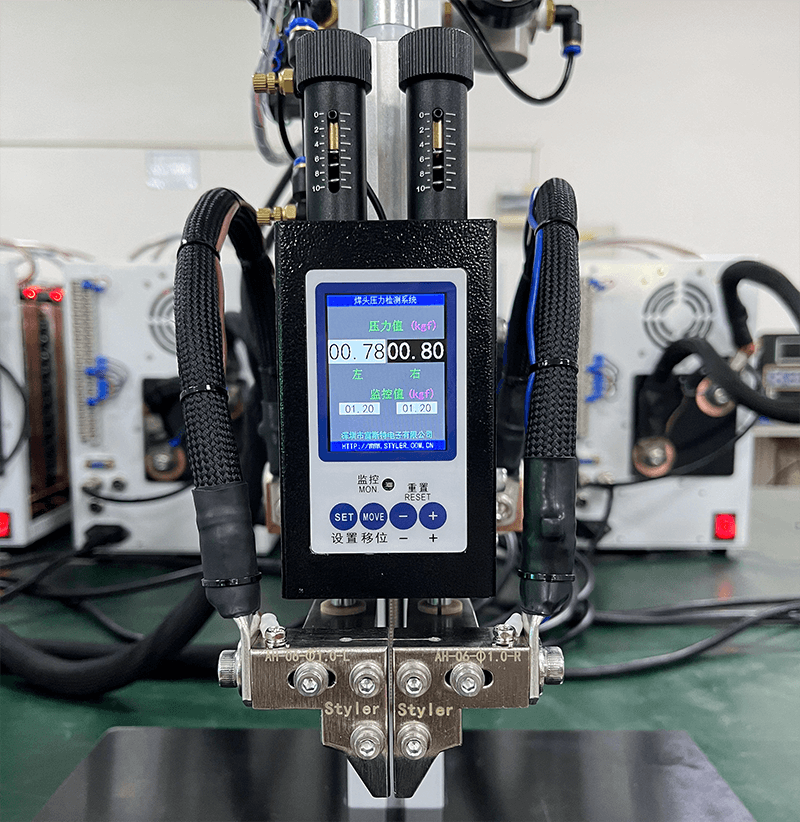

Eketsa sensor ea khatello hloohong ea welding (khatello ea li-clamps mahlakoreng ka bobeli e ka beoa hore e tsitsane, 'me khatello nakong ea welding e ka beoa leihlo)

Hobaneng o re khetha

1. Re 'nile ra tsepamisa maikutlo tšimong ea ho tjheseletsa ka mokhoa o nepahetseng oa ho hanyetsa ka lilemo tse 12,' me re na le linyeoe tse ruileng tsa indasteri.

2. Re na le theknoloji ea mantlha le bokhoni bo matla ba R & D, 'me re ka nts'etsapele mesebetsi e ikhethileng ho latela litlhoko tsa bareki

3. Re ka u fa moralo oa moralo oa sekema sa welding.

4. Lihlahisoa le litšebeletso tsa rona li na le botumo bo botle.

5. Re ka fana ka lihlahisoa tse theko e tlaase ka ho toba ho tloha fekthering.

6. Re na le mefuta e mengata ea lihlahisoa tsa lihlahisoa.

7. Re ka u fa therisano ea pele ea thekiso le ka mor'a thekiso nakong ea lihora tse 24.