Lihlahisoa

Styler 5000A mochini oa solder

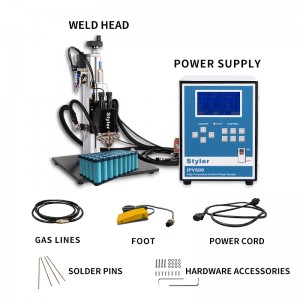

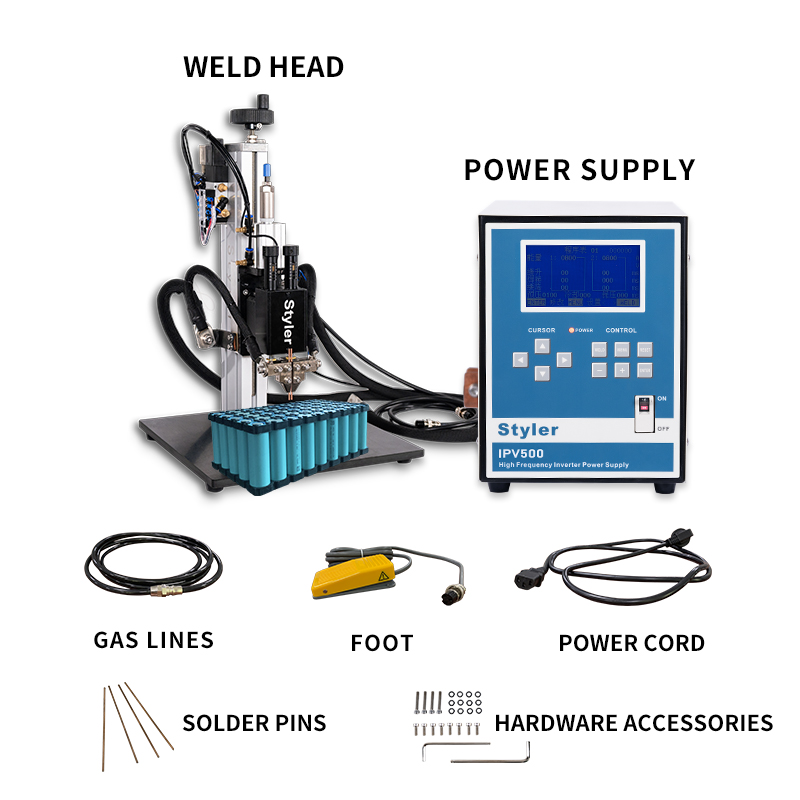

Likarolo tsa Sehlahisoa

Taolo ea mantlha ea nako le nako, taolo ea motlakase e sa feleng, taolo e tsoakiloeng, ho netefatsa mefuta e fapaneng ea tjheseletsa.Sekhahla sa taolo e phahameng: 4KHz.

Ho fihla ho 50 e bolokiloeng mohopolong oa li-welding, o sebetsanang le mosebetsi o fapaneng.

Sefafatsi se fokolang sa welding bakeng sa sephetho se hloekileng le se setle sa welding.

Ho tšepahala ho phahameng le bokhoni bo phahameng.

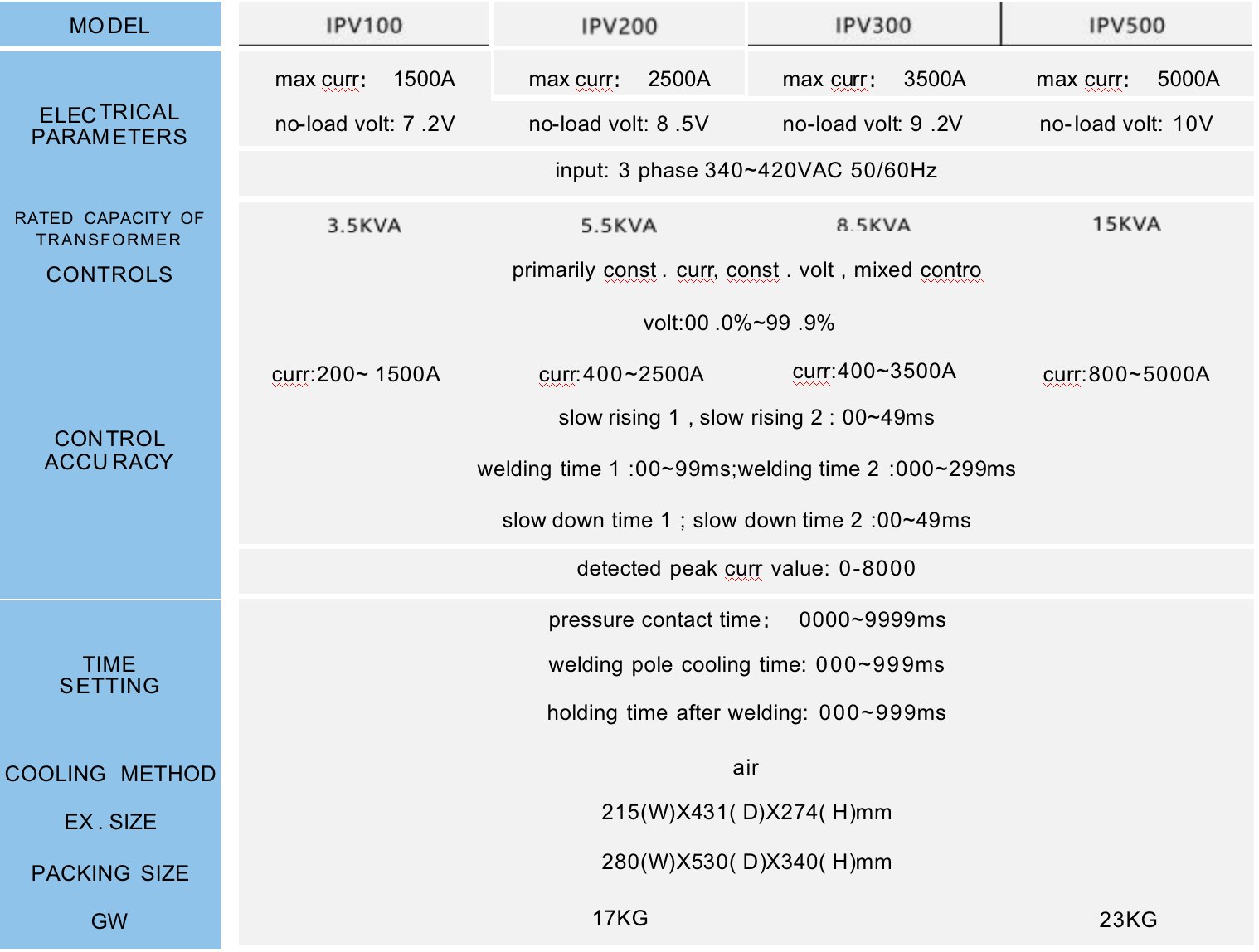

Lintlha tsa Sehlahisoa

Tšobotsi ea Parameter

Ke Hobane'ng ha U Re Khetha

1. Re 'nile ra tsepamisa maikutlo tšimong ea ho tjheseletsa ka mokhoa o nepahetseng oa ho hanyetsa ka lilemo tse 12,' me re na le linyeoe tse ruileng tsa indasteri.

2. Re na le theknoloji ea mantlha le bokhoni bo matla ba R & D, 'me re ka nts'etsapele mesebetsi e ikhethileng ho latela litlhoko tsa bareki

3. Re ka u fa moralo oa moralo oa sekema sa welding.

4. Lihlahisoa le litšebeletso tsa rona li na le botumo bo botle.

5. Re ka fana ka lihlahisoa tse theko e tlaase ka ho toba ho tloha fekthering.

6. Re na le mefuta e mengata ea lihlahisoa tsa lihlahisoa.

7. Re ka u fa therisano ea pele ea thekiso le ka mor'a thekiso nakong ea lihora tse 24.

Tshebeletso ya rona

Tšebeletso ea pele ho thekiso

1. Thusa moreki ho sekaseka morero oa sehlahisoa le ho fana ka tharollo ea welding ea setsebi.

2. Free sampole teko tjheseletsa.

3. Lits'ebeletso tsa meralo ea jig tse nang le tsebo.

4. Fana ka tšebeletso ea ho hlahloba boitsebiso ba ho romella / ho fana.

5. Lihora tse 24 lebelo la maikutlo ka lengolo-tsoibila la ba bang.6. Sheba feme ea rona

Tšebeletso ea ka mor'a thekiso

1.Koetliso ea mokhoa oa ho kenya le ho sebelisa Thepa ka mohala kapa ka tšehetso ea tekheniki ea video.

2.Moenjineri a ka fana ka tataiso ea ts'ebetso ea welding le ho rarolla mathata a fapaneng a tekheniki ts'ebelisong ea lisebelisoa.

3.Re fana ka tiisetso ea boleng ba 1year (likhoeli tse 12).Nakong ea tiisetso, haeba ho na le bothata leha e le bofe ba boleng ka mochine, re tla u nkela sebaka sa likarolo tse ncha ntle le tefo ebe re u romela ho uena ka ho hlahisa thepa ea rona.Mme o fane ka moeletsi wa tekheniki nako efe kapa efe.Haeba ho le mpe le ho feta, re ka romella baenjiniere ba rona fekthering ea hau.